A12: In order to ensure the quality and performance of the assembled PCB, it is necessary to check throughout the SMT assembly process. Multiple types of inspections must be used to reveal manufacturing defects, which can reduce the reliability of the final product. Visual inspection is most commonly used in SMT assembly. As a direct inspection method, visual inspection can be used to indicate obvious physical errors, such as component displacement, missing components, or component irregularity. Visual inspection is not suitable for visual inspection. Tools such as a magnifying glass or microscope can also be used. In order to further point out defects occurring in the welding ball, AOI and X-ray examination can be used after the welding is completed.

A11: PCB after SMT assembly must be cleaned before leaving the shop as the assembled PCB may be covered with dust and reflow soldering residue such as flux, all of which may reduce the reliability of the product to some extent. Therefore, the assembled PCB must be cleaned before leaving the workshop.

A10: Reflow soldering is used in SMT assembly to permanently fix components on the PCB and is done in a reflow furnace containing temperature zones. In the reflow welding process, the solder paste is first melted at high temperature in the first and second stages. As the temperature decreases, the solder paste will harden, so the component will be fixed to the corresponding pad on the PCB.

A9: Chip installation contributes to the core meaning of SMT assembly, which refers to the process by which an SMC or SMD is quickly placed on an SMT component. The pad is left on the PCB pad. Therefore, based on the adhesion of the solder paste, the component will temporarily stick to the board surface.

A8: Solder paste printing is the process of printing solder paste on a pad on a PCB so that the SMC or SMD can be glued to the board via the left solder paste on the pad. Solder paste printing is achieved through the application of templates, which have a number of openings on which the solder paste will remain on the pad.

A7: SMT assembly procedures usually include solder paste printing, chip installation, reflow soldering, AOI, X-ray and rework. A visual inspection is performed after each step of the program.

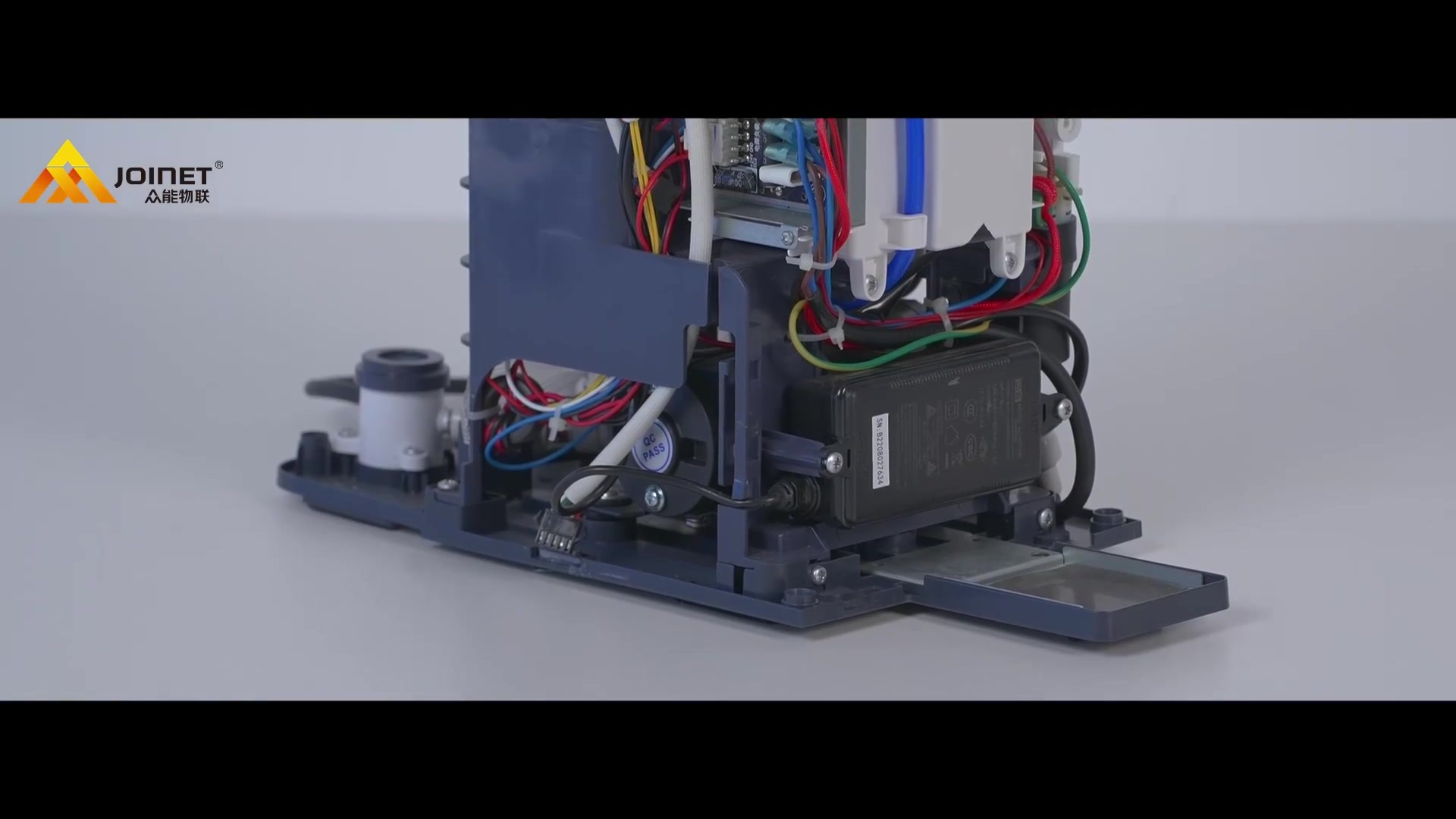

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime