Q12: What type of inspection is used for SMT assembly?

A12: In order to ensure the quality and performance of the assembled PCB, it is necessary to check throughout the SMT assembly process. Multiple types of inspections must be used to reveal manufacturing defects, which can reduce the reliability of the final product. Visual inspection is most commonly used in SMT assembly. As a direct inspection method, visual inspection can be used to indicate obvious physical errors, such as component displacement, missing components, or component irregularity. Visual inspection is not suitable for visual inspection. Tools such as a magnifying glass or microscope can also be used. In order to further point out defects occurring in the welding ball, AOI and X-ray examination can be used after the welding is completed.

Previous Page

Next Page

Previous Page

Next Page

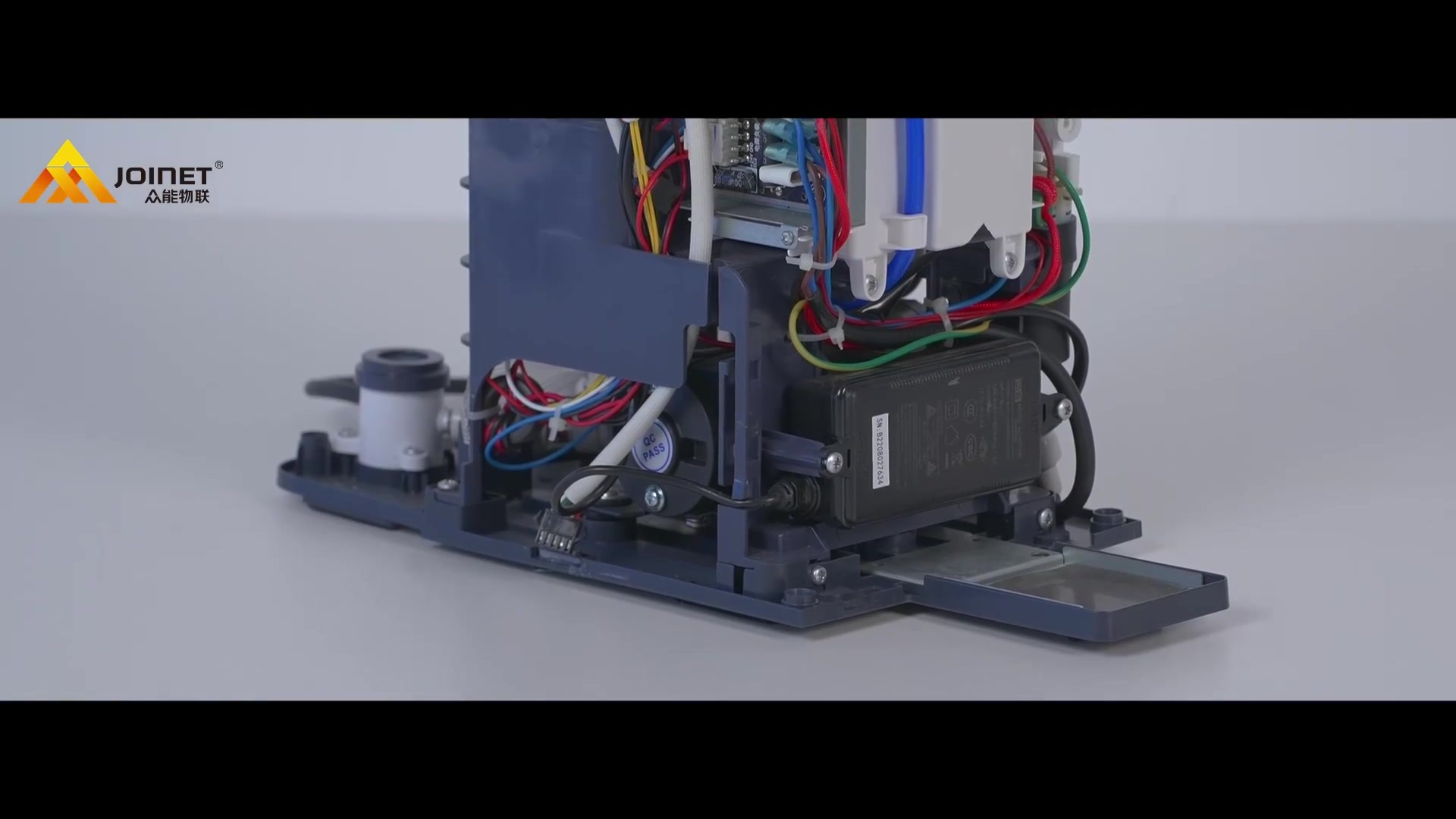

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime