Manufacture

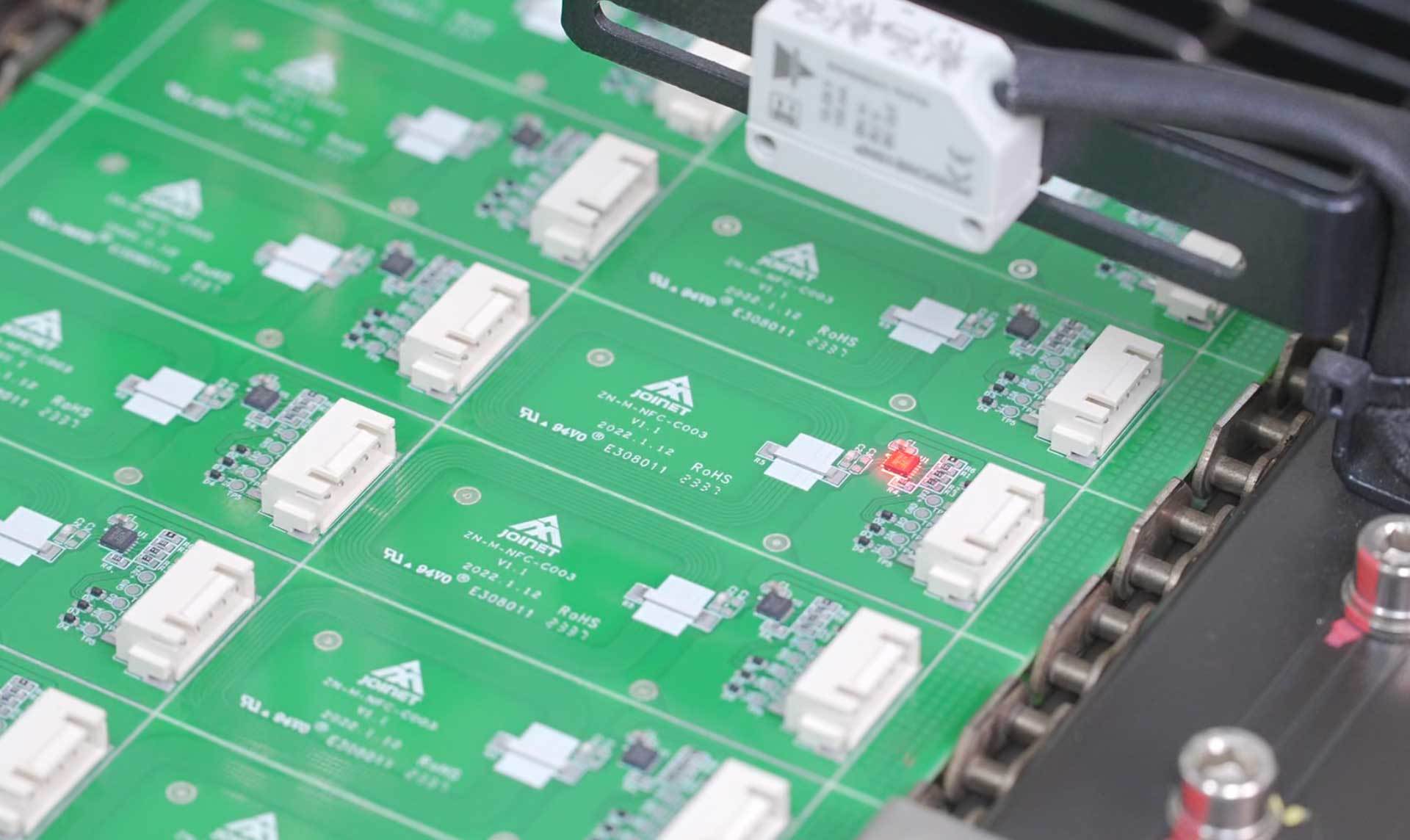

SMT surface mount processing services

1) Control important process links such as IQC incoming material inspection, IPQC process inspection, and OQA factory inspection;

2) Equipped with a professional R&D and engineering team to coordinate with clients on engineering documents and materials;

3) Equip professional sales personnel to coordinate with customers;

4) Supervise the PMC production planning process to ensure delivery time;

5) Using ESD electrostatic protection pearl cotton or electrostatic bags for safe packaging to ensure the safety of the product during transportation;

SMT production capacity

Capable of mounting PCB hard board (FR-4), (metal substrate), PCB soft board (FPC), and soft hard combination PCB

The specifications for mounting components can be applied with a minimum package of 0201Chip/0.35 Pitch BGA

Minimum device accuracy for mounting ± 0.04mm

IC chip mounting accuracy ± 0.03mm

PCB mounting size L50 * W50mm - L510 * W460mm

Thickness of PCB mounting: 0.3mm-4.5mm

Throwing rate, resistance capacity rate, 0.3%

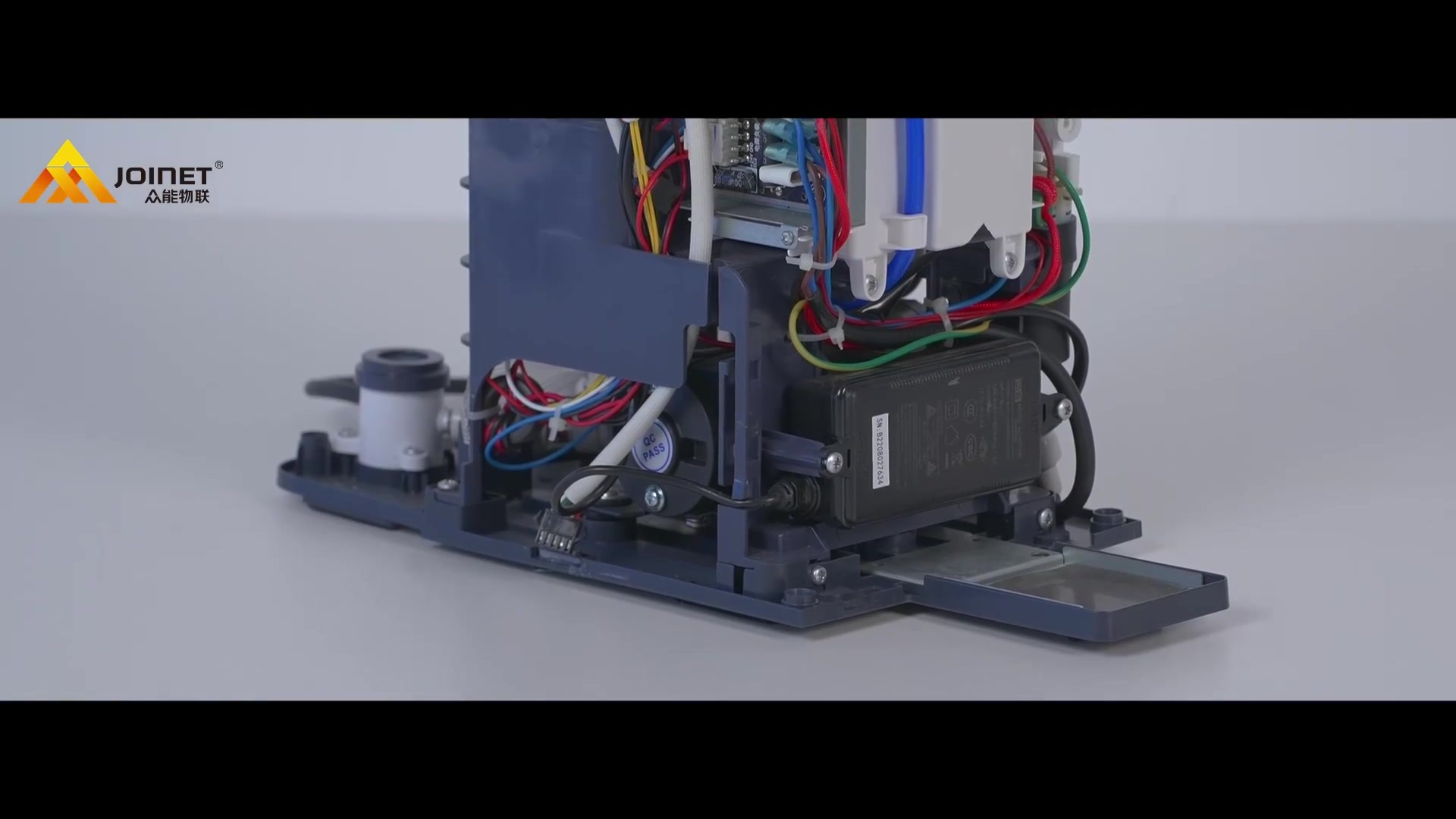

Fully automatic lead-free wave soldering

The wave soldering equipment is a full computer (Windows XP operating system)+PLC control system; The preheating zone adopts a three-stage adjustable speed micro hot air circulation design, which has a more uniform heating effect and precise temperature control; The tin temperature is controlled using PID self feedback algorithm to ensure effective control of tin temperature within+/-1 degrees, and is equipped with an automatic tin adding device; Forced natural air cooling, with the option of selecting an air cooler to meet the cooling slope requirements of lead-free processes; Equipped with intelligent fault diagnosis, automatic recording of device status, and the ability to set different user permissions for operations

Production process: Red glue, solder paste, red glue solder paste mixed process

Minimum spacing between legs of weldable parts: 0.3mm

Welding quality after furnace<100PPM

Online AOI detection

AI algorithm wave soldering pre plugin AOI, system assisted rapid modeling, no need to set any parameters, one click intelligent search for more than 80 devices, support advanced deep AI learning and training model capabilities, computer vision graphics and image processing, can generate SPC management reports, support barcode recognition and MES system integration, and can control quality in real time.

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime