Six prominent ways supply chains benefit from the Internet of Things

Release Time:

2021-10-29

The Internet of Things (IoT) is changing the way we look at everything from cooking and storing food in our homes to tracking products throughout their journey from factory to store shelf.The logistics industry is just the latest in a long line of industries embracing this new connected technology.

The Internet of Things (IoT) is changing the way we look at everything from cooking and storing food in our homes to tracking products throughout their journey from factory to store shelf.

The logistics industry is just the latest in a long line of industries embracing this new connected technology. So what are the supply chain benefits of adopting iot?

Improve inventory through iot asset tracking

Inventory systems are designed to help executives and business owners keep track of the products they have on hand, and if these systems rely on human input and manual counting to update inventory quantities, they are very inefficient.

The Internet of Things can take asset tracking to the next level by attaching a small RFID or Bluetooth tracker to the packaging, which can help provide real-time location information for every item in the supply chain.

By feeding real-time tracking data into warehouse management software, iot asset tracking helps companies keep an eye on inventory levels, prevent shortages, and avoid losses caused by theft.

Improve supply chain transparency

Supply chain transparency has become a growing concern for business owners, as customers are making greener choices and want to know where their products are coming from.

A 2015 study found that 66% of shoppers were willing to pay more for a company's products if it committed to environmental protection and maintained a transparent supply chain.

Supply chain transparency not only helps attract ecologically conscious customers, but a transparent supply chain enabled by the Internet of Things helps prevent disruptions throughout the supply chain.

With transparency, there is nothing to hide if something goes wrong with one of your suppliers. In case of difficulties, all information is at hand.

Real-time temperature tracking for cold chain transportation

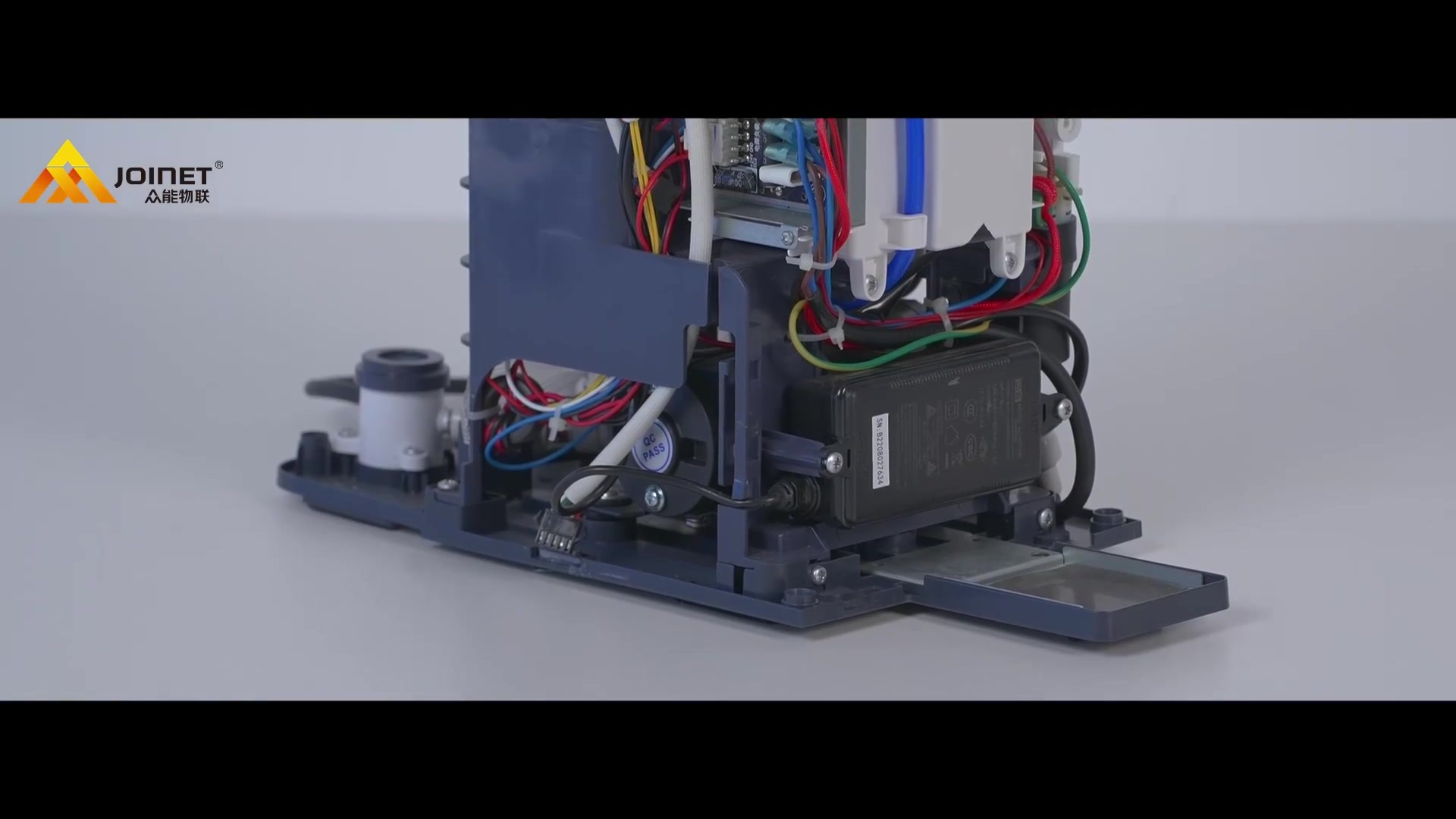

Cold chain transport is an integral part of the food, beverage, drug and chemical supply chains. Every product needs to be kept below a certain temperature during transportation and storage. For items such as medicines, a temperature change of less than two degrees can ruin an entire shipment.

Adding the Internet of Things to cold chain transportation can provide real-time temperature tracking during transportation and storage, alerting the cargo owner or company director if there is any change in the internal temperature of the truck or warehouse.

Predictive maintenance to avoid downtime

Most warehouses and supply chains have an established maintenance schedule, taking equipment out of service on a strict schedule to inspect and repair it to prevent it from failing when it is most needed. While this is the most commonly used maintenance strategy, it is not the best.

A study by the ARC Advisory Group found that only 18 percent of equipment failures were due to aging. The rest happens randomly, so supply chain owners need a new strategy to make sure it doesn't.

The Internet of Things eliminates much of the need for preventive maintenance. Iot sensors track the health of each device and feed that data back into warehouse management software, which in turn alerts supervisors and maintenance teams when certain devices need maintenance, thereby preventing costly down time and equipment failures.

Fleet management

If your warehouse is also responsible for fleet management -- from trucks used for deliveries to forklifts and cranes inside the facility -- the Internet of Things can help improve the quality of fleet management. Equipping your fleet with iot sensors can help you track vehicle maintenance levels and alert you when something goes wrong or needs to be tweaked.

Iot sensors can also track vehicle fuel efficiency and even driver behavior to ensure that drivers are safe while driving their vehicles.

Smoother last mile delivery

Last kilometer deliveries are the most challenging because they take up so much time. Since the advent of e-commerce, companies have been looking for ways to enhance this, and the Internet of Things could be the perfect solution. Thanks to real-time traffic analytics, GPS and the Internet of Things can recommend routes that are optimized to reduce fuel waste and time spent in traffic jams.

The same asset tracking technology used in warehouses can also facilitate consumer package tracking to simplify last-mile delivery.

total

The Internet of Things is growing exponentially. Supply chain and logistics are not the only industries that could benefit from iot technology, but the future growth of the industry cannot be achieved without iot. (Compile iothome)

Reprinted in the House of Things

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime