How can the Internet of Things help manufacturers operate more efficiently

Release Time:

2021-05-27

Smart factories are now a reality. The Internet of Things is building a new manufacturing environment by connecting automated production technologies and intelligent manufacturing processes.Over time, advanced methods and equipment entered the manufacturing field, raising production capacity to a ne

Smart factories are now a reality. The Internet of Things is building a new manufacturing environment by connecting automated production technologies and intelligent manufacturing processes.

Over time, advanced methods and equipment entered the manufacturing field, raising production capacity to a new level. The progress of technology year by year has brought us from the first Industrial Revolution to the fourth.

The current industrial revolution, with its unique methods and technologies, is redefining operational efficiency.

Whereas previous revolutions revolved around specific areas of the industrial sector, the fourth Industrial Revolution is driven by connectivity. In this article, we will explore how the Internet of Things is changing various aspects of manufacturing and the challenges that the industry must overcome to become part of the Internet of Things.

Welcome the fourth Industrial Revolution

To understand the true application of the Internet of Things in manufacturing, it's worth looking back at the industrial revolution. Since the 17th century, there have been four revolutionary changes in manufacturing.

The first was the introduction of water power to improve the efficiency of steam engines such as gin, looms, and conveyors.

The second came in the 1870s, and this revolution brought us electricity. The invention of power stations and light bulbs powered the automation of factories and gave rise to the concept of mass production.

The third revolution occurred around the 1960s, when digital technology and computers were introduced to replace analog technology. This stage opened the world to globalization.

Fourth, this is the age of cognitive manufacturing. In the current phase, big data, iot sensors, robotics and predictive analytics will converge to form a new definition of iot in industrial manufacturing operations.

The fourth Industrial Revolution has brought about a glorious era for manufacturing. Companies are beginning to understand the huge impact of the Internet of Things in their production processes, and they have begun to talk to companies that develop the Internet of Things to figure out ways to leverage the Internet of Things in manufacturing.

The Internet of Things in manufacturing

As the implementation of the Internet of Things in manufacturing becomes a new norm, manufacturers are reaping multiple benefits from this implementation.

1. Inventory management

By connecting devices such as smart shelves and forklifts to wireless communications and RFID and sensors, manufacturers will be able to get a real-time view of their inventory. At the production level, sensors connected to shelves and machines will be able to provide real-time data on inventory depletion and reminders to reorder.

2. Predictive maintenance of assets

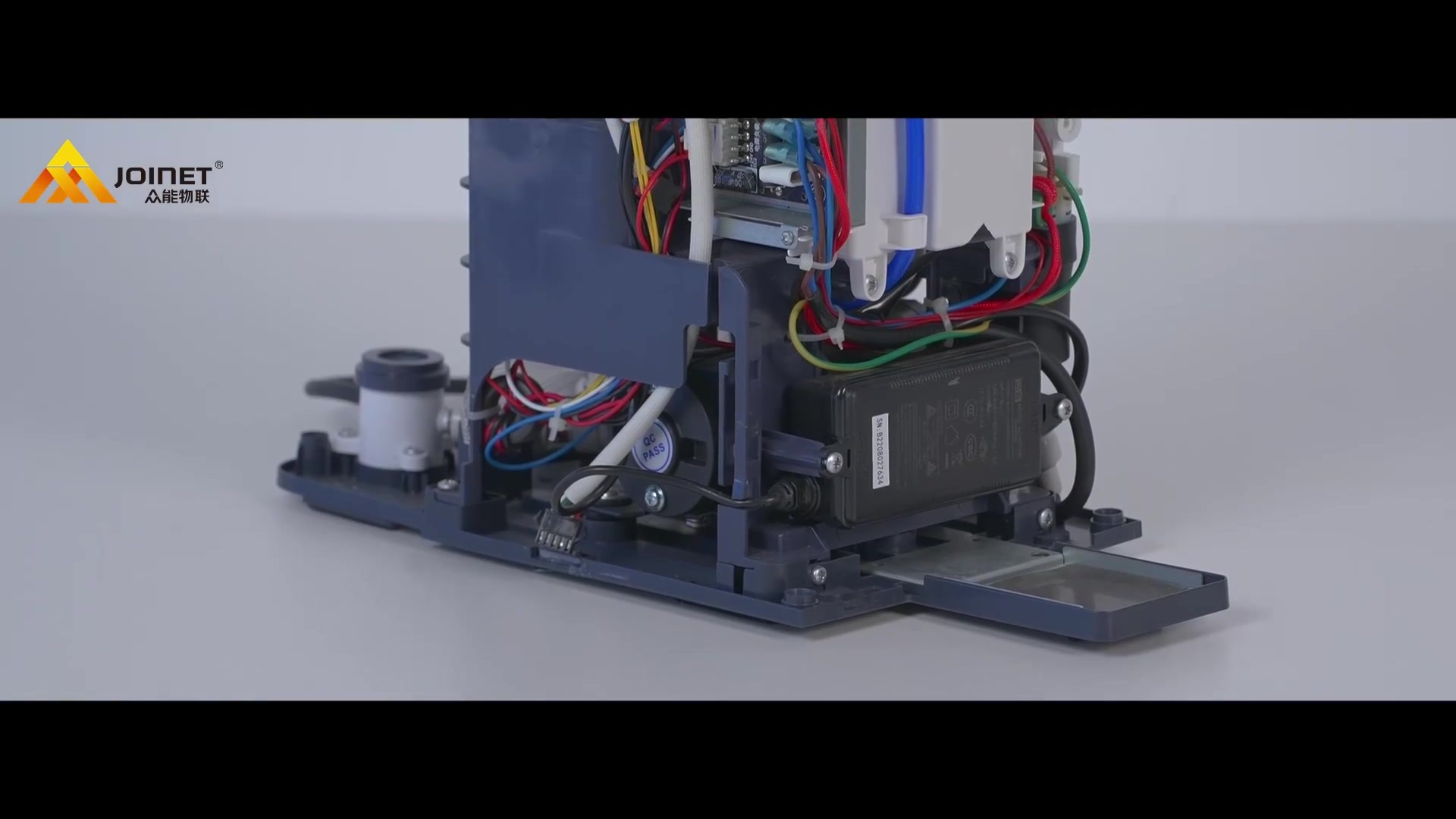

With sensors and RFID, the Internet of Things can monitor the health of devices such as smart machines and vehicles, and then schedule maintenance based on usage.

There are a number of alert-driven systems based on the Internet of Things that provide insight into mechanical problems that may need to be replaced or repaired. It can not only improve asset utilization, but also avoid expensive outage maintenance costs.

3. On-site service

The Internet of Things enables manufacturers to improve their service capabilities. Sensors and networked devices allow businesses to proactively service appliances, equipment and installations, while planning on-site services in a more cost-effective manner. Iot solutions in manufacturing can also provide visibility in the supply chain to monitor location, product status in transit, delivery schedules, and more.

4. Labor management

Information from assets, machines and mobile devices can help companies gauge employee productivity. Instead of managers having to walk around the factory to see how their employees are doing, they will be able to get a view of productivity metrics that are automatically created and updated in real time.

5. Quality assurance

The positive role of the Internet of Things in manufacturing can be demonstrated by adding quality assurance programs to operational processes. This technique helps to measure changes in product flow and predetermined product specification parameters.

The result is increased efficiency at an overall level because products are developed to specifications, defective production is stopped in real time, and repairs are made to prevent system and equipment outages.

6. Cognitive operation

The idea behind cognitive operations is to be able to take current data and analyze it in order to make decisions around better operations, safety and quality. System linking technologies like the Internet of Things can help analyze structured and unstructured data such as videos or photos to bring greater certainty to business operations and decision-making.

7. Optimize and smart resources

The final benefit of iot in manufacturing revolves around optimizing resources (energy, people, knowledge, and equipment). Best practices must be followed to keep costs low and increase overall production efficiency and participation. With the combination of cognitive insight and the Internet of Things, data such as usage, geographical location, and environmental conditions can be used to:

Better worker safety and effective labor force management

Improve workers' productivity and expertise

▲ Reduce energy consumption of equipment and buildings.

Despite the growing use of iot in manufacturing, manufacturers still face some challenges when adopting iot solutions.

Barriers to iot adoption in manufacturing

Data interoperability

One of the biggest obstacles facing iot application developers is data interoperability. In a traditional manufacturing environment, environmental data is divided by function or department area. This makes production, scheduling, engineering, and quality difficult to relate to or compatible with for analysis.

Lack of iot skills

The Internet of Things is still in its development stage, which means that hiring people with the expertise to take advantage of it remains a challenge. To make matters worse, when we study iot applications in manufacturing, not only technical skills but also experience in analytics, big data, embedded software development, electronics and IT security are required.

Data leakage

As iot devices and software become more common in different industries and manufacturing, security concerns are growing. Every iot application development company must follow a security-first approach and adhere to all security best practices to ensure its security. (Compile iothome)

Reprinted in the House of Things

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime