Why is the Industrial Internet of Things finally seeing its golden age

Release Time:

2021-03-11

Over the past few years, a number of device manufacturers have begun using the Industrial Internet of Things (IIoT) to deploy remote monitoring, predictive maintenance, devices as a Service (EaaS), and other types of new Industry 4.0 applications. These applications allow companies to merge their in

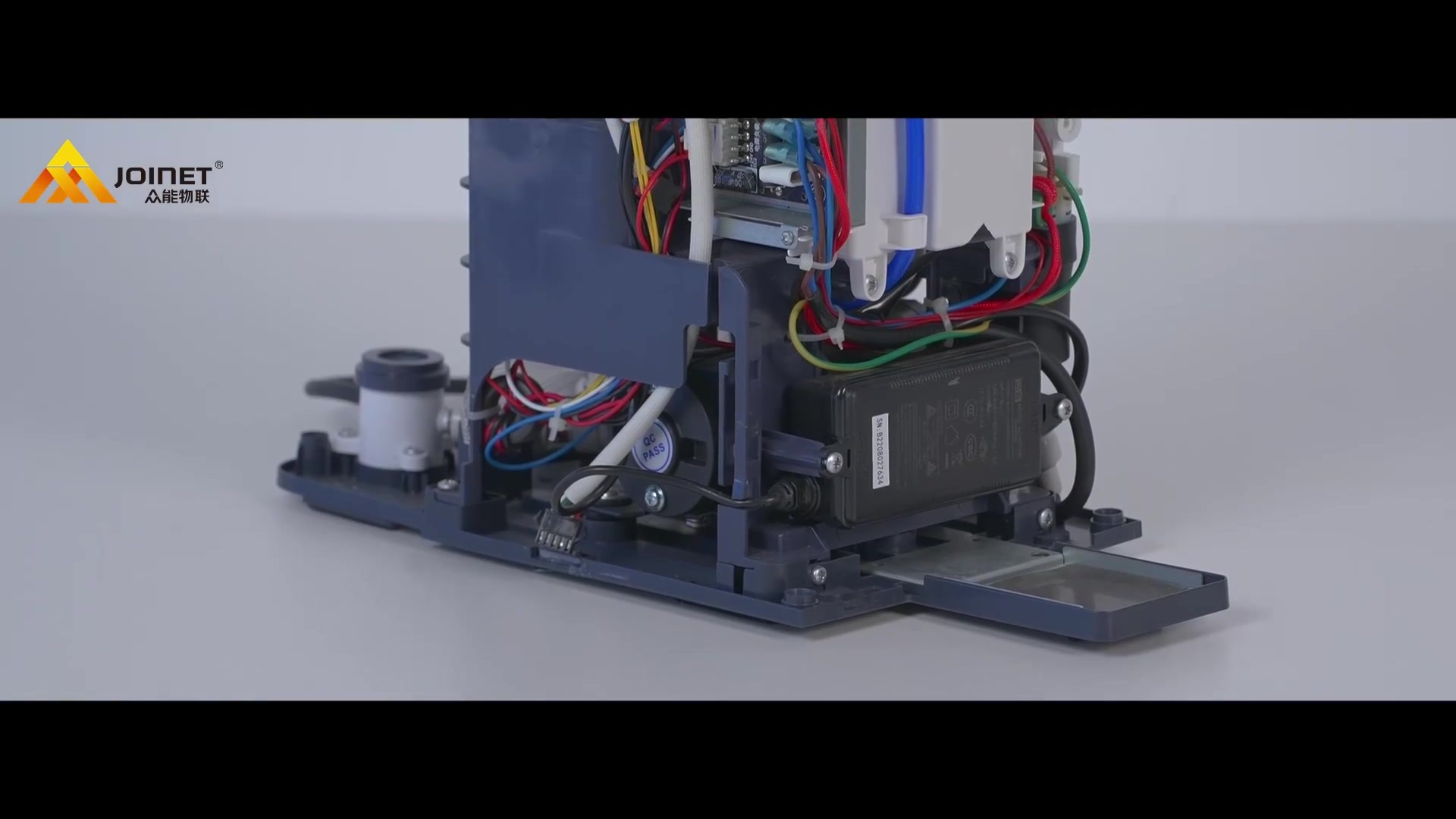

Over the past few years, a number of device manufacturers have begun using the Industrial Internet of Things (IIoT) to deploy remote monitoring, predictive maintenance, devices as a Service (EaaS), and other types of new Industry 4.0 applications. These applications allow companies to merge their industrial equipment OT systems with IT systems to create "smart" air compressors, bio-waste collectors, liquid fertilizer storage tanks, energy storage systems, and other types of industrial equipment.

With this new smart industrial equipment, these companies are changing the way they do business, using equipment OT system data to reduce equipment downtime, reduce maintenance costs and launch new revenue-generating services.

However, the vast majority of device manufacturers have yet to participate in this Industry 4.0 revolution.

What's the reason? The industrial Internet of Things is very complex. In particular, until recently, companies have not acquired expertise in edge devices, embedded software, wireless connectivity, cloud software, device communication protocols, Internet of Things network security, and other complex disciplines that require the integration of a device's OT systems with its IT systems in order to make them intelligent.

However, there are new solutions that simplify the Industrial Internet of Things (IIoT) and enable it to bridge the gap between early adopters and the majority of device manufacturers. Thanks to new cloud technologies, data choreography and other technologies, as well as their innovative integration with wireless services, these new solutions enable manufacturing companies to quickly and easily integrate OT systems with IT systems.

Two new solutions in particular - the cloud-based Internet of Things Application platform and the Edge-to-cloud Infrastructure solution - remove much of the complexity involved in building, deploying, maintaining and updating Industry 4.0 applications.

Extend and simplify the cloud

The cloud has fundamentally changed manufacturing. With the cloud, device manufacturers can now outsource much of the complex work involved in buying, managing, extending, and securing the computing infrastructure needed to run their IT applications to cloud service providers. Instead of having to build and maintain their own data centers or other internal infrastructure, device makers can build and run IT applications on Microsoft Azure, AWS, or other cloud-based application platforms.

Major cloud service providers (like Microsoft and Azure IoT Central) and smaller app support platform companies (like Losant's Losant Enterprise IoT platform) are adding data lakes, workflow engines, visualization, and other features that companies need to build IIoT applications to their platforms. With these fully hosted, cloud-based iot application platforms, device manufacturers can develop, manage, monitor and control their Industry 4.0 applications using the same programming skills as their IT applications.

Cloud-based iot application platforms are increasingly enabling device manufacturers to leverage cloud development skills to develop Industry 4.0 applications. However, iot application platforms do not provide these companies with the edge-to-cloud infrastructure solutions they need to extract data from industrial devices with modules, routers, and other iot edge devices, and then securely and efficiently coordinate this data transfer to the cloud.

Until recently, equipment manufacturers needed expertise in various industrial equipment communication protocols if they wanted to build such infrastructure solutions. In addition, they must:

1. Set up and manage the wireless connection services needed to transfer data from edge devices to the cloud.

2. Write apis to integrate this data into the cloud.

3. Implement an iot security plan to protect their data from malicious actors from the moment it is generated at the edge until it is ingested by the cloud.

Fortunately, new edge-to-cloud infrastructure solutions have emerged that embed all of these capabilities into their solutions, thereby eliminating the need for these companies to acquire the expertise needed to build these capabilities themselves. For example, many of these solutions contain the communication protocols needed for edge devices to extract data from industrial devices.

They include Global connectivity services that allow these devices to automatically connect to cellular wireless networks around the world, and have cloud apis that enable device manufacturers to easily integrate their device data into cloud-based iot application platforms.

In addition, these solutions often include distributed processing and data choreography technologies that enable manufacturing companies to automatically deliver security patches to their edge equipment. Many of these data orchestration technologies also support functions beyond security.

For example, they help device makers optimise data transmission from edge devices to the cloud, thereby reducing data transmission costs and reducing energy consumption for battery-powered edge devices. They also enable device manufacturers to update the application rules for their edge devices as business requirements change.

evolution

Edge-to-cloud infrastructure solutions and cloud-based iot application platforms together address the need for device manufacturers to not have access to all the complex expertise needed to integrate their OT systems into their IT systems.

Using these solutions, even manufacturing companies with little or no knowledge of the Internet of Things can now create remote monitoring apps that send out alerts if a device's operating data indicates it may fail soon, and then repair the device remotely before sending technicians to make adjustments.

They can visualize their device data so that their performance can be evaluated over time. They can track how many customers are using their devices, allowing them to start new pay-as-you-go services to reduce upfront capital expenditure for customers, while also creating new long-term revenue streams for them. In addition, they can transfer device data to their ERP, CRM, billing, and other IT applications, where it can be used for further automation or to generate valuable insights.

More manufacturing companies are expected to deploy Industry 4.0 applications as edge-to-cloud infrastructure solutions and cloud-based iot application platforms increasingly enable more simplified IIoT to bridge the gap between early adopters and other device manufacturers. By using these Iiot applications to automate error-prone manual processes, generate insights to improve decision making, and provide new services to customers, these companies will transform their businesses, as well as the global economy.

Reprinted in the House of Things

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime