The new infrastructure accelerates the digital transformation of enterprises, and ADI promotes the a

Release Time:

2020-08-29

In Recent Years, With the Accelerated Integration of the New Generation of Information Technology Represented by the Internet of Things, CLOUD Computing, Big Data and AND AN RTIFICIAL Intelligence with TRADITIONAL Industries, a new round of global technology, of new production methods and organizati

In Recent Years, With the Accelerated Integration of the New Generation of Information Technology Represented by the Internet of Things, CLOUD Computing, Big Data and AND AN RTIFICIAL Intelligence with TRADITIONAL Industries, a new round of global technology, of new production methods and organizational methods And business models continue to emerge, which are driving the intelligent transformation of the global industrial system. According to the "Industrial Internet Industry Economic Development Report (2020 ) " recently released by the China Accord ademy of Information and Communications Technology, it is expected thatthe industrial Internet will become one of the most active growth areas in the national economy in 2020. It is expected that the economic scale of China's industrial Internet industry will up to 3.1 trillion yuan.

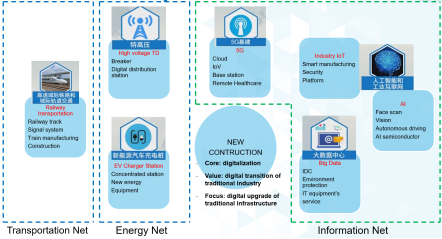

There is no doubt that the current upsurge of " new infrastructure " will be an important driving force for the development of China's industrial Internet industry. " Some experts have further interpreted and classified the seven major areas of " new infrastructure " into information network, transportation network and energy network, but no matter from any point of view, digitalization is the core key element in the layout and construction of " new infrastructure " and will definitely Drive a new round of development of its related industries,Especially the accelerated development of the Industrial Internet of Things ( IIOT), making it an important role in the center stage of the digital transformation of industrial manufacturing, connecting the equipment layer and the network layer, providing platform, software and application layers It has laid a solid foundation and will fully open up the key data flow in the entire industrial system. " Yu Changtao ( Roger ), ADI China's industrial automation industry marketing manager, said in an interview with the media recently.

Guided by digitalization, accelerate the transition and upgrading of traditional industries to new industries

The industrial field has also been considered one of the largest application scenarios of the Internet of Things. Through the network interconnection, data intercommunication and system interoperability of industrial resources, the Industrial Internet of Things can realize flexible configuration of manufacturing raw materials, on-demand execution of manufacturing processes, reasonable optimization of manufacturing processes, and rapid adaptation of manufacturing environments to achieve efficient use of resources. , so as to build a service-driven new industrial ecosystem, which itself is carried out around digitalization. With the advancement of digitalization, the Industrial Internet of Things can also bring fundamental changes in two aspects to the entire industry, including the digital upgrade of traditional equipment and the new products and new business models generated during the upgrade process.

" In fact, the Industrial Internet of Things has undergone digitization, networking, and intelligence upgrades on the basis of traditional industries. The core of which is still digitalization, and networking and intelligence are digital upgrades." Yu Changtao emphasized " The industrial logic behind the Industrial Internet of Things is also the integration and application of the three technologies of sensor technology, communication technology, and information processing technology that are becoming more and more mature. We can well associate its layer structure with ADI products, which will include ADI 's rich and comprehensive Research on sensor series, wired and wireless communication network technology, and cloud-based software algorithms. ”

Deploying industrial IoT communication networks, gradually moving from wired to multi-combined

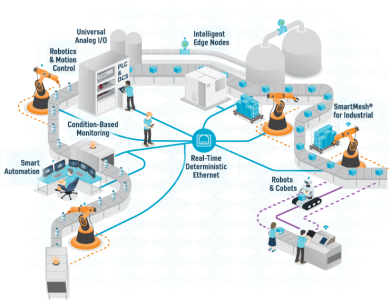

The advantage of the Industrial Internet of Things is the ability to make better use of the ever-increasing data collected by sensors to make better decisions, and in the entire industrial automation system, whether data can be acquired and transmitted in a timely manner depends on network connectivity. To cope with the ever-increasing volume of data, network technology as well as manufacturing processes and methods must be continuously improved. Smart, connected automation environments require digitally connected control systems, industrial equipment, production line robots, and more to create and share information. The way these machines communicate and the factory communication network deployed is at the heart of the enterprise and the key to enabling the Industrial Internet of Things.

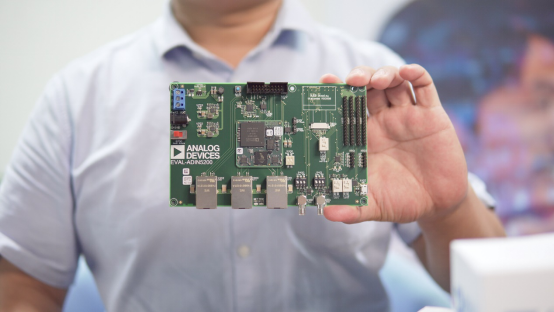

From the perspective of transmission network, the communication methods are nothing more than wired and wireless. So far, industrial sites are still dominated by wired communication. Wireless communication is used as a supplement in some application scenarios. Industrial Ethernet has begun to play an increasingly important role. effect. Decades of development have led to numerous industrial Ethernet protocols and topologies. More and more industrial automation technology suppliers and manufacturers hope to obtain an open communication platform independent of manufacturers. Therefore, future IIoT applications must support various common network topologies, such as PROFINET , EtherNet/IP ® , EtherCAT ® , POWERLINK ® and other common industrial Ethernet protocols, as well as line and ring topologies and star topologies. Yu Changtao introduced in detail that the fido5000 series products created by ADI are real-time Ethernet, multi-protocol (REM) switching chips with two Ethernet ports, and are programmable IEEE 802.3 10 Mbps/100 Mbps Ethernet Internet Protocol Version 6 (IPv6) and Internet Protocol Version 4 (IPv4) switches that can virtually support any Layer 2 or Layer 3 protocol. Plus, it can connect to any host processor, allowing developers to use their own processor and their development environment.

It is worth mentioning that fido5000 also supports time-sensitive networking (TSN) . In the future, the requirements of TSN - based industrial ethernet applications will be able to meet the very demanding real-time requirements of applications such as motion control or security. In an industrial setting, even a millisecond of communication latency can negatively and costly impact a manufacturer's product quality, throughput, and efficiency. The ADIN1300 , among the new Chronous TM series industrial Ethernet solutions launched by ADI , is further committed to solving the important challenges of deploying industrial Ethernet connections with low latency and smaller package size to ensure real-time reliable industrial communication, thereby reducing Industrial Ethernet network cycle time. This is an industrial Ethernet physical layer (PHY) product to help manufacturers address key Industry 4.0 and smart factory communication challenges, including data integration, synchronization, terminal connectivity, and system interoperability.

有线通信领域,包括RS-485在内的典型现场总线技术与传统过程控制和电机控制网络,ADI基于领先的模拟技术、隔离产品以及处理器等的开发,提供了广泛的软件可配置IO、现场仪器仪表、高效伺服驱动系统等方案。“例如ADI最新推出的四通道、软件可配置输入/输出套件AD74413R与AD74412R,将有助于开发现场可配置远程I/O单元,将传统的现场设备与网络连接,实现传统仪器仪表与高层级以太网网络的融合。”于常涛举例说明。

In industrial environments, low-power, stable and reliable wireless sensor networks are becoming a supplementary option for network connections in more industrial application scenarios due to the convenience of deployment and maintenance. The SmartMesh IP network in the 2.4GHz frequency band provided by ADI is one of the outstanding representatives . The biggest feature of this network is that it achieves 99.999% high data transmission reliability Mesh network, and the power consumption is extremely low. At the same time, SmartMesh is also a time synchronization network, which can accurately synchronize the time of each node, which is convenient for many occasions that need synchronization. Due to its high reliability, it is very suitable for industrial applications that require high reliability of network transmission and wish to use maintenance-free. For SmartMesh IP , ADI not only provides high-performance chips and productized modules, but can even provide customers with a complete set of solutions. SmartMesh networks have been used in global data centers, industrial automation, wind power generation, oil pipelines, transportation and other fields.

Intelligent upgrade of industrial equipment starts with accurate " diagnosis " of production line status

Whether it is industrial Ethernet or wireless sensor network, its greatest value is the landing of industrial applications, including the surge of high-quality sensors, reliable connections and data analysis, and the increasing degree of automation of intelligent nodes for precise data capture and monitoring of sensors. Location tracking requirements are also increasing day by day. Sensors can be divided into many types in the industrial field, such as the well-known temperature, pressure, flow, liquid level monitoring, etc., which have been widely used several years ago. CBM ( Condition Based Monitoring ) , which has been mentioned more and more in recent years, has introduced vibration monitoring as the core technology, collecting and analyzing the vibration status of rotating equipment for product performance, production efficiency and added value. Further improvement, this is the application with the most practical economic significance and the easiest to implement.

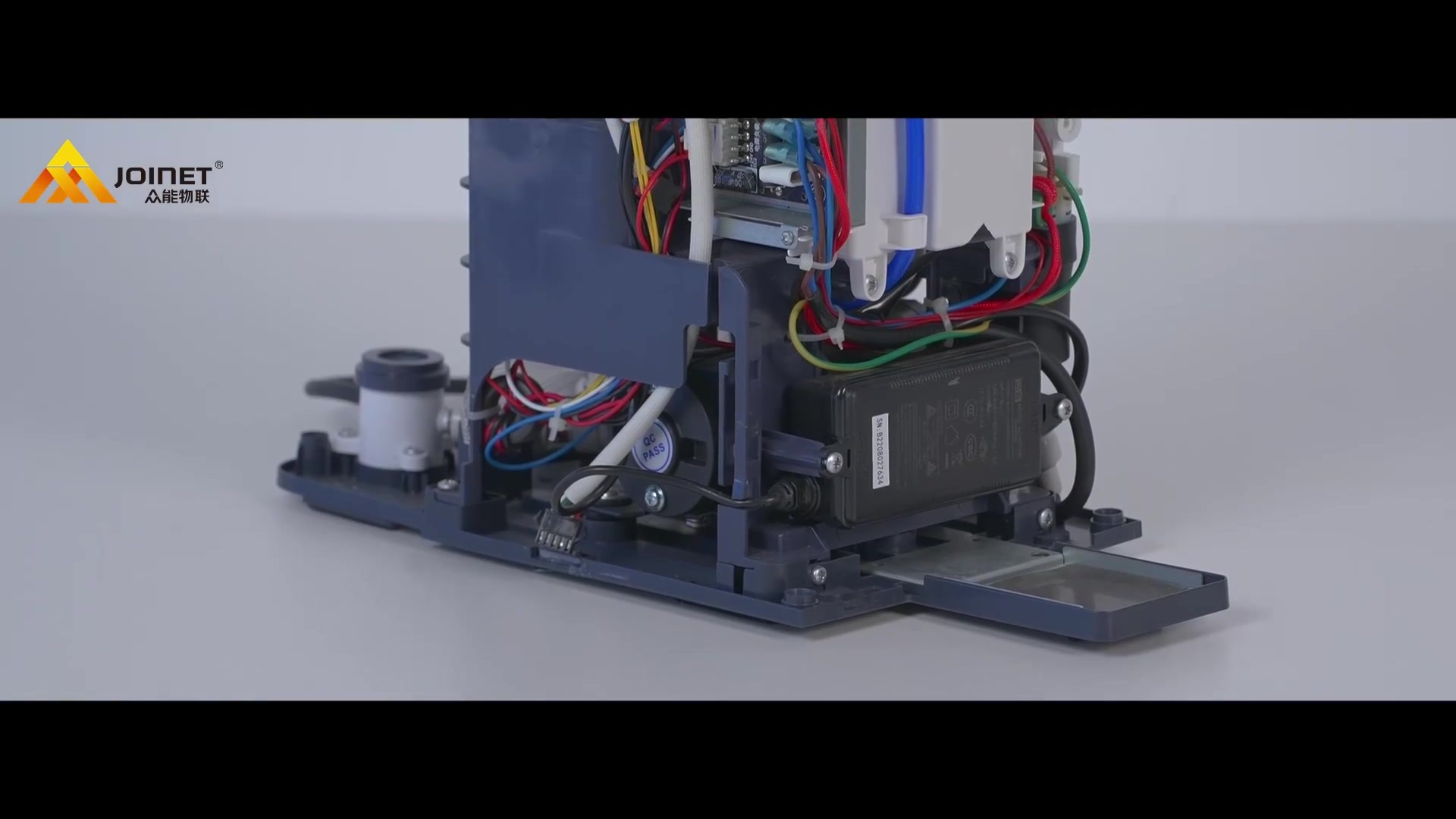

For example, everyone involved in the maintenance of industrial equipment knows that the vibration emitted by the equipment is very important information, and the health of the equipment can be judged through the vibration, which can greatly reduce the maintenance cost. The realization of equipment condition monitoring system relies on ADI's series of high-performance MEMS accelerometer products in industrial applications . Yu Changtao said: "The ADXL100x series single-axis accelerometers are optimized for industrial condition monitoring applications, with a measurement bandwidth of up to 50 kHz , a g range of up to ±100 g , and ultra-low noise performance. Within the measurement range of the ADXL100x series condition monitoring accelerometer. The integrated module product ADcmXL3021 also combines high-performance vibration detection and various signal processing functions, which can track vibration signals on many machine platforms, which can simplify the condition monitoring system. Smart Sensor Node Development Cycle. ”

The ADI team is not only working on using human interpretation of vibration for industrial equipment monitoring, but also enabling detection of abnormal behavior and diagnosis from the sound of equipment. ADI 's OtoSense architecture is an equipment health monitoring system that supports what we call computer hearing, allowing computers to understand the main indicators of sound and vibration emitted by equipment, and can identify potential problems in factory machinery or car engines before problems become serious. question. It is worth mentioning that in order to further strengthen the predictive maintenance solution based on condition monitoring, ADI has also acquired Test Motors , a company specializing in the predictive maintenance of electric motors and generators, to integrate ADIf's original industrial condition monitoring solution technology, and OtoSense 's AI platform sensor interpretation software combined with Test Motors ' monitoring capabilities creates a more optimized solution that provides more advanced and comprehensive health monitoring of machines by capturing a wider range of potential faults.

Integrated and customized solutions to efficiently facilitate the implementation of industrial IoT applications

The deployment of " new infrastructure " is accelerating. How to seize the opportunity of the industrial Internet of Things under the " new infrastructure " ? In recent years, with the shortening of product development pace and time-to-market, customers have more and more requirements for semiconductor component suppliers. They are no longer satisfied with only providing corresponding components, but hope for a higher level of support. ADI In the past few years, we have also worked hard according to this logic. For example, based on traditional superior products, ADI can not only provide the chip itself, but also integrate the chip into a system-level solution based on our understanding of the customer's system, which greatly shortens the customer's R&D risk and R&D time.

Yu Changtao said that the previous industrial condition monitoring module ADcmXL3021 provided a full explanation for ADI 's systematic design support. It uses three accelerometers ADXL1002 widely used in vibration monitoring , and also uses a low-power MCU , coupled with a very good and complete mechanical structure that has been tested and verified for modular packaging. become. As a systematic solution, it perfectly solves the anxiety of customers' application landing: choosing a suitable sensor chip requires the support of corresponding software algorithms, and at the same time, the design of the mechanical structure must be considered. The three ADXL1002 inside the ADcmXL3021 can detect vibration in three directions in the X , Y , and Z axes. The low-power MCU integrates some FFT algorithms, which can transmit some data in the time domain or frequency domain, as well as some original data waveform. Its entire mechanical structure design is also very small, and has undergone complete product-level certification and verification. This is the common practice when ADI currently provides customized and modular solution support for customers.

" Nowadays, perhaps the islands of industrial information and insight data that we cannot access still exist, but with the accelerated promotion of the ' new infrastructure ' policy, the deployment of the Industrial Internet of Things is becoming more and more popular, and the challenge of traditional industrial transformation and upgrading will turn to how to efficiently collect and operate equipment. Data, ensuring its security during data transmission, and how to use these data to fully enhance business value. " Yu Changtao emphasized , " ADIhas deep industrial expertise, technical experience and a wide range of product solutions. It will effectively help you accelerate the digital upgrade transition from traditional industries to future smart factories. "

Reprinted from RFID World Network

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime