RFID warehouse automation flexible solutions to solve the e-commerce industry warehousing pain point

Release Time:

2020-08-28

With the rise of the e-commerce industry, the logistics industry has become a battlefield where all kinds of capital have no smoke. It is imperative to solve the pain points of low warehousing automation and high labor costs in the industry. EOS, a high-tech enterprise focusing on logistics technolo

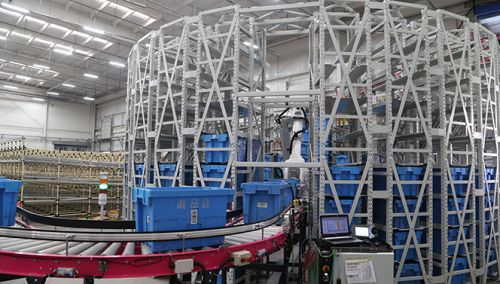

With the rise of the e-commerce industry, the logistics industry has become a battlefield where all kinds of capital have no smoke. It is imperative to solve the pain points of low warehousing automation and high labor costs in the industry. EOS, a high-tech enterprise focusing on logistics technology and automation solutions with robots as its core, has studied the business scenarios of automated warehouses in depth for many years, actively created new picking methods and storage location strategies, and improved storage area utilization and storage space for corporate customers. Work efficiency has been actively explored in warehousing automation. Among them, the robot bin-type automatic warehouse developed by EOS has solved the problems of secondary caching and multi-category picking in e-commerce and other industries, and further created value for customers.

Targeted solutions to industry pain points

Different from ordinary warehouses, e-commerce warehouses have higher requirements for product turnover speed, storage efficiency, and delivery accuracy. There are five major difficulties in the e-commerce warehouse : " large daily shipment orders, heavy sorting workload, large peak and valley differences, large number of product categories, and large inventory " . For this reason, EOS has specially developed a robot material Box automatic warehouse.

Precise design improves warehouse operation efficiency

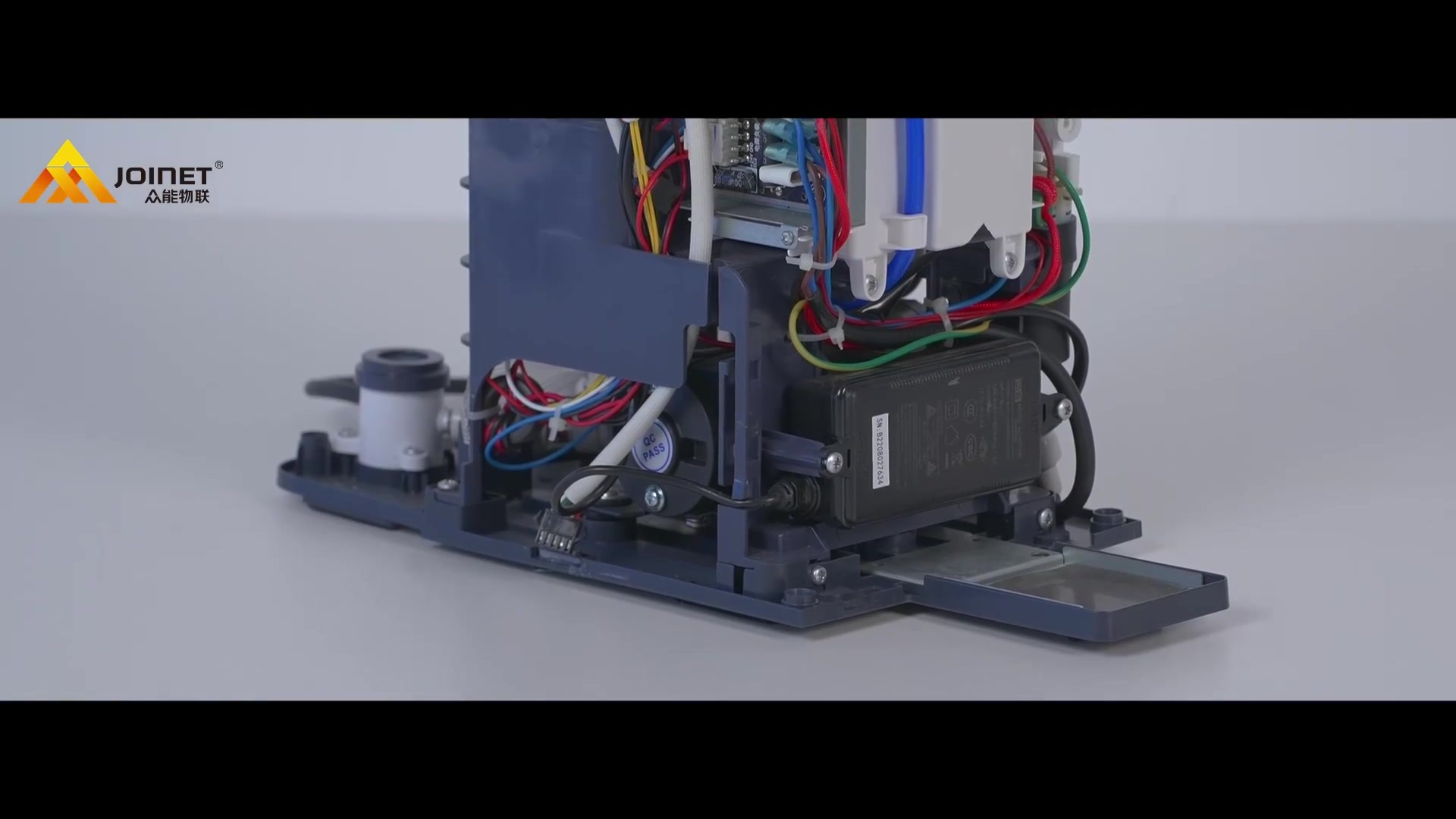

EOS automated warehouse uses robotic manipulators to use bins as storage units to perform 360° rotating sorting of goods in the ring circle of bins . Compared with other storage methods, the robotic material box automatic warehouse can use containers, boxes or shelves to store small parts , which can make full use of the space height of the shelf and improve the utilization rate of storage space; the robot material box automatic warehouse is used on pallets and shelves The installed RFID electronic tag enables the robot arm to shorten the picking time of a single item, reduce the error rate, and save the time and labor costs of storing the item when the robot arm accesses and picks the item, thereby achieving higher transfer efficiency in the automated warehouse .

Automated warehouse enhances enterprise competitiveness

In today's increasingly competitive market, building an automated warehouse that meets modern needs and introducing automated storage equipment has become a necessary measure for e-commerce companies to seize market opportunities. This set of flexible logistics solutions created by EOS to meet the needs of e-commerce enterprises for warehousing automation is mainly used for warehouses with many categories of storage objects and a limited number of each category. It is an effective solution for warehousing automation for such warehouses. Since then, 1 billion parcels in and out of the warehouse have been realized a day, and the goal of warehouse automation has been realized. As a one-stop intelligent warehousing solution provider, EOS can provide customized warehousing automation solutions for various enterprises to meet the different needs of different enterprises for warehousing automation, and upgrade traditional warehousing logistics to adapt to the modern economy. develop. For example, EOS provides a set of robotic material box automatic warehouse solutions for a large cosmetics e-commerce company. This solution fully realizes the informatization and automation of storage, transportation, palletizing, sorting and other material flows, covering 80% of the workflow in the company's warehousing and logistics system has helped the company realize warehousing automation and enhance the strength of the enterprise.

Today, the EOS robot bin-type automatic warehouse fully meets the automation, specialization and refinement needs of the e-commerce retail industry for warehousing and logistics. With the development of 5G network in the future, EOS will continue to rely on its technological advantages and talent advantages to get through the " last mile " of logistics , and to help accelerate the development of China's economy with more efficient and automated intelligent storage solutions!

Reprinted from RFID World Network

Guangdong Joinet IOT Technology Co.,Ltd

Manufacturing Base:

Joinet Technology Park,No. 168 Tanlong North Road,Tanzhou Town,Zhongshan City,Guangdong Province,China

Pre Sales Hotline:19966308713 13823973022

Switchboard:0760-8663 0003 (transferred) 523

Pre Sales Email:sw@znaiot.com

Contact Us:

Looking forward to your call anytime